Vessel and Machine Shop

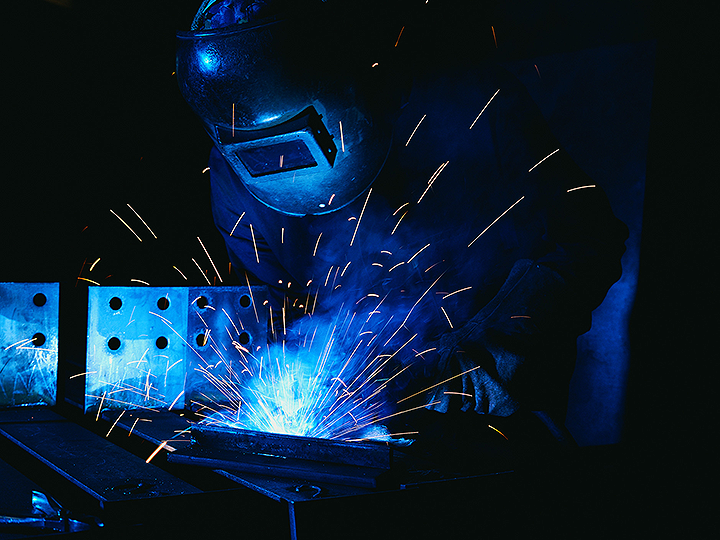

Shop & Field Fabrication & Repairs

H&S Constructors has a full-service machine shop available 24/7 to serve your needs. Shop capabilities include:

- Heat exchanger repair

- Pipe fabrication

- Structural fabrication

- Vessel fabrication

- Vessel repair

- ASME code work

- Flange and exchanger resurfacing

Shop Facilities

Fabrication Shop No. 1 (*) 21,000 Sq. Ft. w/ 2-20 Ton Bridge Cranes 70' x 150' 26' Underhook

Machine Shop (*) 12,500 Sq. Ft. w/ 2-5 Ton Bridge Cranes 20' x 150' 18' Underhook

Pipe Shop No. 1 6,000 Sq. Ft. w/ 2-10 Ton Bridge Cranes 60' x 100' 18' Underhook

Fabrication Shop No. 2 (*) 10,500 Sq. Ft. w/ 2-5 Ton Bridge Cranes 20' x 150' 18' Underhook

Fabrication Shop No. 2: (2) 5 Ton Air Operated Bridge Cranes 20′ X 150′, 18′ Underhook

Fabrication Shop No. 2: (2) 20 Ton Electric Bridge Cranes 70′ X 150′, 26′ Underhook

Machine Shop: (2) 5 Ton Electric Bridge Cranes 80′ X 150′, 18′ Underhook * Shops located within 300 ft. of Cargo Docks 8-14 & 15 with 45′ of water

Machine Shop (*) 12,500 Sq. Ft. w/ 2-5 Ton Bridge Cranes 20' x 150' 18' Underhook

Pipe Shop No. 1 6,000 Sq. Ft. w/ 2-10 Ton Bridge Cranes 60' x 100' 18' Underhook

Fabrication Shop No. 2 (*) 10,500 Sq. Ft. w/ 2-5 Ton Bridge Cranes 20' x 150' 18' Underhook

Fabrication Shop No. 2: (2) 5 Ton Air Operated Bridge Cranes 20′ X 150′, 18′ Underhook

Fabrication Shop No. 2: (2) 20 Ton Electric Bridge Cranes 70′ X 150′, 26′ Underhook

Machine Shop: (2) 5 Ton Electric Bridge Cranes 80′ X 150′, 18′ Underhook * Shops located within 300 ft. of Cargo Docks 8-14 & 15 with 45′ of water

Machine-Vessel Shop Equipment

Springfield 18″ x 40″ Lathe

Lodge & Shipley 28″ x 120″ Lathe

Lathe 15″ X 48″ Between Centers

Lathe 20″ X 60″ Between Centers

Lathe 28″ X 144″ Between Centers

Summit Vertical Turret V0348

Vertical Boring Mill 79″ Swing, 59″ Under Rail

Vertical Boring Mill 168″ Swing, 90″ Under Rail

Radial Drill 4′ Travel, 11 1/2″ Column

Shop Made 100 Ton Hyd. Press

Horizontal Band Saw

Planer With Air Clutch 48″ X 14′

Lehman Hydratol 24″ x 96″ Lathe

CNC Vertical Milling Center

CNC Mill Tronics ML26 26″ x 120″ Lathe

Profi Master Lathe 22″ x 80″

106″ Froriep Vertical Boring Mill

30″ Bullard Boring Mill

Shibaura 72″ Vertical Boring Mill

Woodard & Power Planner Mill

Mills, Kearney & Trecker Vertical Mill

Lodge & Shipley 28″ x 120″ Lathe

Lathe 15″ X 48″ Between Centers

Lathe 20″ X 60″ Between Centers

Lathe 28″ X 144″ Between Centers

Summit Vertical Turret V0348

Vertical Boring Mill 79″ Swing, 59″ Under Rail

Vertical Boring Mill 168″ Swing, 90″ Under Rail

Radial Drill 4′ Travel, 11 1/2″ Column

Shop Made 100 Ton Hyd. Press

Horizontal Band Saw

Planer With Air Clutch 48″ X 14′

Lehman Hydratol 24″ x 96″ Lathe

CNC Vertical Milling Center

CNC Mill Tronics ML26 26″ x 120″ Lathe

Profi Master Lathe 22″ x 80″

106″ Froriep Vertical Boring Mill

30″ Bullard Boring Mill

Shibaura 72″ Vertical Boring Mill

Woodard & Power Planner Mill

Mills, Kearney & Trecker Vertical Mill

Welding Equipment

8 & 12 Bank Welding Machines

Sub-Arc

Manipulators (10′ Tall x 14′ Arm & 7′ Tall x 12″ Arm

CNC Torch Systems 8′ x 20′ (1″ Plasma Cut and 6″ Flame Cut)

Sub-Arc

Manipulators (10′ Tall x 14′ Arm & 7′ Tall x 12″ Arm

CNC Torch Systems 8′ x 20′ (1″ Plasma Cut and 6″ Flame Cut)

ASME Code Vessel Fabrication

H&S Constructors designs, manufactures, and repairs pressure vessels to meet ASME code, Section VIII Div. 1, as well as the most stringent customer specifications.

We are certified for ASME code stamps:

- “U”, authorizing the manufacture of pressure vessels at our location or in the field according to the provisions of the ASME Boiler and Pressure vessel code for code welding;

- “S”, authorizing the manufacture and assembly of power boilers at our facilities and in the field according to the provisions of the ASME boiler and pressure vessel code; and

- “R”, authorizing metallic repairs and/or alterations at our facility and extended for field repairs or alterations in accordance with the ASME boiler and pressure vessel code.

H&S Constructors has more than one hundred weld procedures at our disposal, including SAW, GMAW, FCAW, GTAW, and SMAW. We employ highly skilled weld technicians, including rig welders for demanding offshore platform work. From mild steel to exotic alloys, H&S Constructors is experienced in fabricating vessels in a broad range of materials. We also resurface and mill tube-sheet, channel heads, and other flange gasket surfaces.